In the ever-evolving aerospace industry, the quest for materials that offer both strength and lightness has led to groundbreaking innovations. Among these, lightweight composite materials stand out for their transformative impact on aircraft design and performance. Their ability to provide unparalleled strength while significantly reducing weight makes them a cornerstone of modern aviation engineering.

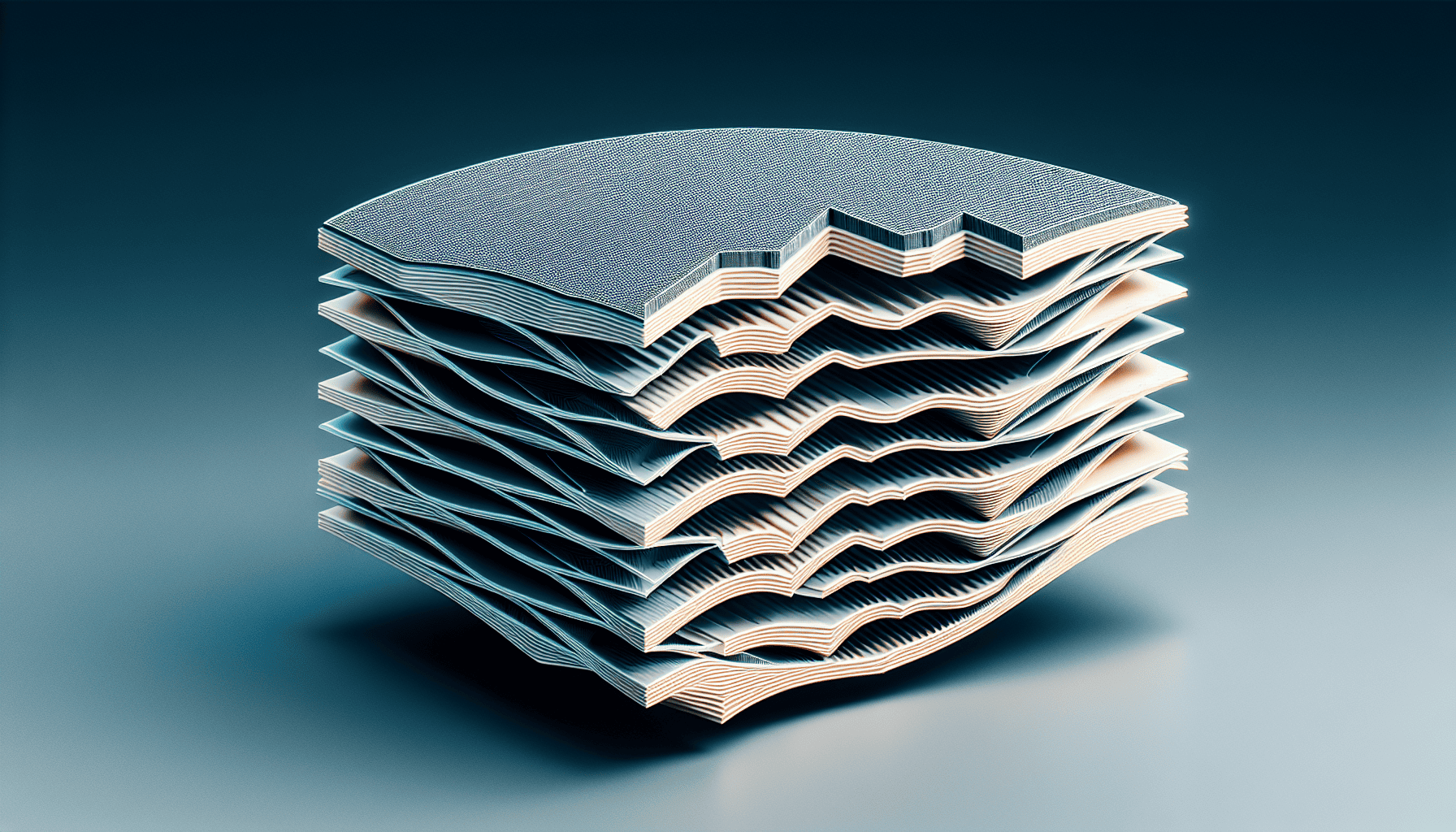

Composite materials are engineered by combining two or more distinct materials to create a new material with properties superior to the individual components. In the context of aerospace applications, these composites typically consist of a matrix (such as polymers) reinforced with fibers (like carbon or glass fibers). The resulting material exhibits remarkable attributes, including high tensile strength, reduced weight, and resistance to corrosion.

One of the most significant advantages of lightweight composite materials is their contribution to fuel efficiency. Reducing an aircraft's weight by just a few percentage points can lead to significant fuel savings. This is not only economically beneficial, reducing operational costs for airlines, but also environmentally friendly, as it leads to lower carbon emissions. As the aviation industry strives to meet global sustainability targets, lightweight composites play a crucial role in developing greener aircraft.

Besides fuel efficiency, these novel materials enhance aircraft performance. Their inherent strength and durability contribute to increased payload capacity and improved aerodynamic features. This allows for more flexible design possibilities, enabling engineers to craft aircraft with optimized shapes and forms for better lift and drag characteristics. Additionally, the superior fatigue resistance of composite materials extends the lifespan of aircraft components, contributing to longer service intervals and reduced maintenance costs.

The safety aspects of composite materials should not go unmentioned. Their excellent energy absorption characteristics make them an ideal choice for enhancing the safety of aircraft in the event of an impact. The ability to dissipate energy efficiently reduces the risk of catastrophic failure, providing added protection for passengers and crew.

Moreover, the adaptability of lightweight composite materials allows engineers to tailor them to specific requirements. For instance, by adjusting the orientation and type of fibers used within the matrix, it's possible to customize the strength, flexibility, and weight of the material to meet the precise demands of different aircraft components, such as wings, fuselages, or tail sections.

While the benefits of these advanced materials are clear, challenges remain. The production and repair processes for composite materials are often more complex than those for traditional metallic counterparts. However, ongoing innovations in manufacturing techniques, such as automated fiber placement and resin transfer molding, are progressively overcoming these hurdles, making it easier and more cost-effective to utilize composite materials on a wider scale.

In conclusion, lightweight composite materials represent a pivotal advancement in aerospace technology. Their unique combination of strength, lightness, and customizability not only improves aircraft design and efficiency but also contributes to a more sustainable and safe aviation industry. As research continues to push the boundaries of what these materials can achieve, the future of aircraft design looks set to be lighter, stronger, and decidedly more innovative.